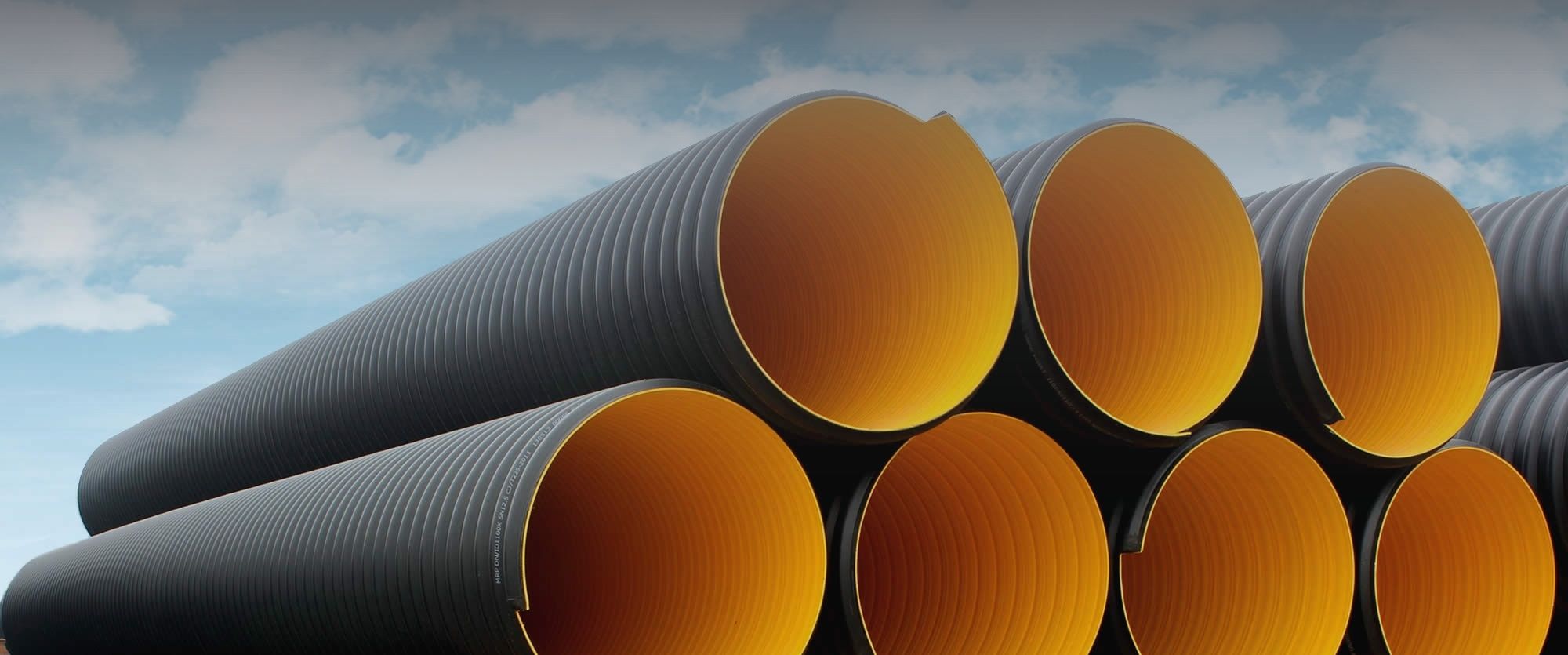

Durable and Reliable Infrastructure Solutions: Kuzeyboru Corrugated Pipes

Kuzeyboru corrugated pipes are manufactured according to the international standard TS EN 13476-3, available in nominal diameters ranging from 100 mm to 1000 mm with or without sockets, and as steel-reinforced pipes in diameters between 800 mm and 2400 mm according to the TSEK-2 standard. Thanks to their special molds and high-quality production, Kuzeyboru corrugated pipes are indispensable for your projects.

Our Corrugated Pipe Products

Material Specifications

Material Specifications

The pipes are made from polyethylene (PE) raw material. To facilitate the manufacturing of components compliant with TS EN 13476-3 standards, specific additives are incorporated into this base material. Spiral type B pipes may include a support profile made from other polymers in addition to PE.

Material Properties of Pipes and Fittings

Property | Standard | Unit | Value |

Melt Flow Index (MFI) at 190°C, 5 Kg | TS EN ISO 1133-1 | g/10 min | ≤ 1.6 |

Density | TS EN ISO 1183-1 | Kg/m³ | ≥ 930 |

Hardness | TS EN ISO 868 | Shore D | 63 |

Heat Resistance (150±2°C) | TS ISO 12091 | Heating time: e ≤ 3 mm 30 min | No delamination, cracks, or bubbles should be observed in the pipe |

Mechanical and Performance Properties of PE Pipes and Fittings

Property | Standard | Unit | Value |

Ring Stiffness SN 4 | TS EN ISO 9969 | kN/m² | ≥ 4 |

Ring Stiffness SN 16 | TS EN ISO 9969 | kN/m² | ≥ 16 |

Ring Stiffness (SN): Kuzeyboru corrugated pipes meet the SN ring stiffness values ranging from SN4 to SN16 as prescribed by TS EN 13476–3 and tested according to ISO 9969.

Ring Flexibility: According to TS EN ISO 13968, pipes withstand deformation of up to 30% of the pipe diameter under pressure without any cracking, breaking, or deformation.

Impact Resistance: Tested per TS EN ISO 3127, samples conditioned at 0°C withstand impact by free-falling weights appropriate for each diameter without cracking.

Leakage Test: According to EN TS EN 1277, pipe systems with elastomeric sealing rings and fittings can withstand 0.5 bar water pressure for 15 minutes without leakage.