Every project has its own unique dynamics. Kuzeyboru GRP pipes are designed to respond to these dynamics with advanced technology, engineering expertise, and a sustainable production approach. Featuring high strength, full corrosion protection, and long-lasting structural properties, these pipes deliver maximum performance in infrastructure projects. Kuzeyboru is not just a pipe manufacturer; it is your professional solution partner offering customized solutions for your projects.

What Are GRP Pipes?

GRP (Glass Reinforced Polyester) pipes are durable and flexible composite pipes made by combining fiberglass with a thermoset resin matrix. Known for their high fracture resistance and lightweight structure, GRP pipes are chemically resistant, non-magnetic, and permeable to radio signals, making them preferred across various industries. Thanks to their adaptability to different applications, they are widely used especially in the chemical, construction, and energy sectors.

Kuzeyboru GRP (Glass Reinforced Polyester) pipes are born from the fusion of advanced engineering power and sustainable manufacturing principles. Sustainability is embraced at every stage of production; from raw material selection to the final product, aiming for a low carbon footprint and applying environmentally friendly production techniques. Thanks to innovative formulations and production methods developed at the Kuzeyboru R&D Center, GRP pipes are engineered to withstand harsh environmental conditions. Moreover, manufacturing can be tailored to the specific technical requirements of each project, maximizing both engineering flexibility and application efficiency. Kuzeyboru GRP pipes are not only strong and durable but also represent a commitment to quality, environmental awareness, and engineering expertise.

Kuzeyboru’s environmentally conscious, durable, and high-quality GRP pipes provide an economical and long-lasting solution for your projects.

Advantages of Kuzeyboru GRP Pipes

Manufactured with high quality and advanced technology, Kuzeyboru GRP pipes receive full technical support from Kuzeyboru’s Field Support and Engineering teams from project inception to delivery.

Key advantages include:

- Weigh only 1/10 of concrete pipes and 1/4 of steel pipes, making handling easier.

- Nested design allows for cost-efficient transportation.

- Equipped with Reka-type and integrated gasket sleeves for fast and practical installation

- Sleeve systems resistant to high pressure ensure safe usage.

- Resistant to chemicals and environmental effects without the need for extra coatings.

- Smooth inner surface prevents sediment buildup, ensuring high fluid flow efficiency.

- Can withstand instantaneous pressure changes up to 40%..

- Offer a service life of 50 years or more.

- Enable energy savings with lower capacity pumps.

Kuzeyboru fiberglass reinforced pipes, with their lightweight structure, long service life, and high durability, are among the best solutions for infrastructure projects.

Applications of GRP Pipes

- Drinking Water Lines: Ensures safe water transport in distribution and transmission networks.

- Wastewater and Sewerage: Corrosion-resistant structure ideal for wastewater discharge systems.

- Irrigation Systems: Provides highly efficient solutions for agricultural irrigation projects.

- Pressure Drainage Lines: Suitable for water discharge in industrial and municipal infrastructures.

- Sea Discharge and Intake Lines: Durable structures for seawater and industrial fluid applications.

- Power Plants: Preferred in cooling water lines and thermal power plants.

- Industrial Facilities: Used in petrochemical, mining, and other industrial plants due to chemical resistance.

- Hydroelectric Plants: Reliable solutions for water conveyance channels and piping systems.

- Trenchless Infrastructure (Jacking Pipes): Suitable for micro-tunneling and trenchless installation methods.

Benefits of GRP Pipes

- Resistant to chemicals and water.

- Lightweight for easy handling and installation.

- High mechanical strength.

- Longer service life compared to alternative materials.

- Reduced maintenance due to corrosion and clogging resistance.

- Easily shapeable and adaptable to different applications.

- Low electrical and thermal conductivity, ensuring safe usage.

- Environmentally friendly production and usage.

GRP Pipe Pricing / Price List

GRP pipe prices vary depending on pipe diameter, pressure class, stiffness level, and application area. Raw materials used in production, special coating options, and project-specific technical requirements also play a significant role in pricing.

Kuzeyboru Glass Reinforced Polyester Pipes and fittings combine high quality with competitive pricing. Through meticulous teamwork from production start to finish, we deliver the most suitable product for your needs. Highlighted by durability, lightweight construction, and long service life, GRP pipes are custom-manufactured to provide the most efficient solutions for diverse projects.

For detailed price lists and project-specific solutions, please contact our expert team to learn about the most suitable KUZEYBORU glass reinforced pipe options for your requirements.

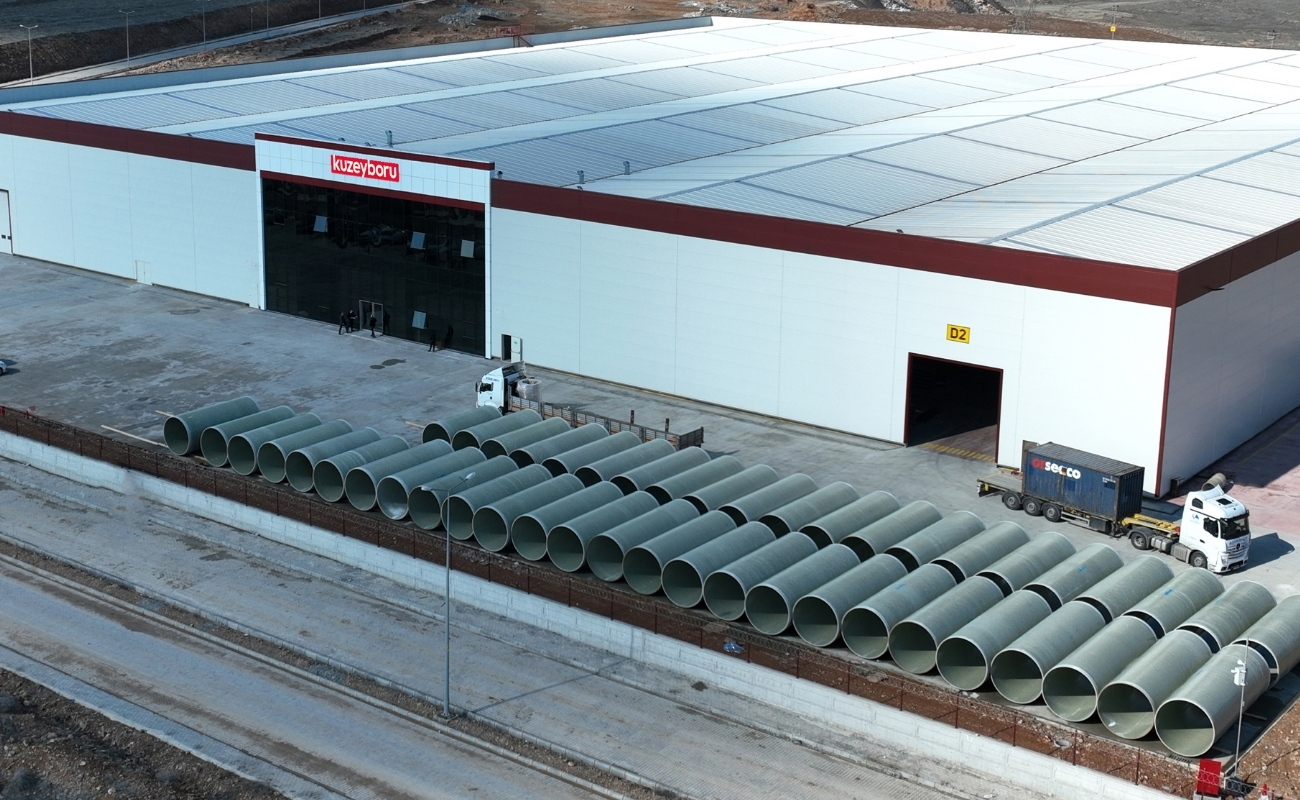

Our CTP composite pipe production facility, established on a 64,368 m² site in Malatya, continues to lead the sector with its advanced technology and quality-driven approach. This is not just a manufacturing plant; it is a center where innovative ideas come to life and each pipe is produced with meticulous care. Our CTP pipes, manufactured using continuous fiber winding (CFW) machines, are available in a broad diameter range from 300 mm to 4,000 mm. This allows us to offer our customers extensive solution flexibility for both small-scale projects and large industrial applications. Produced in accordance with international standards, our pipes reach every corner of the world with their high strength, eco-friendly structure, and guaranteed long service life. The Malatya factory best exemplifies our commitment to delivering quality products and adapting to evolving technology.

GRP pipes are manufactured by carefully combining fiberglass, resin, and silica sand. These materials ensure the pipes gain high strength both axially and circumferentially, while also providing excellent resistance to peak loads. The main raw materials used in the production process are fiberglass, thermoset resin, and silica sand. These materials are processed using three different methods:

- Continuous Fiber Winding Method

- Spray-Up Casting Method

- Fiber Winding Method

At Kuzeyboru, we use the latest and most advanced technology the Continuous Fiber Winding Method. This method offers significant advantages in both production speed and product quality compared to other techniques:

- Long Pipe Production: While pipe length is limited to 6 meters with other methods, the continuous fiber winding method allows production of pipes 12 meters, 15 meters, or even longer depending on transportation conditions. This greatly facilitates installation in large scale projects and reduces costs.

- High Production Speed: This method is much faster than other production techniques, enabling rapid fulfillment of customer demands.

- Homogeneous Structure: The continuous fiber winding method creates a uniform structure throughout the pipe surface, ensuring consistent strength and performance at every point.

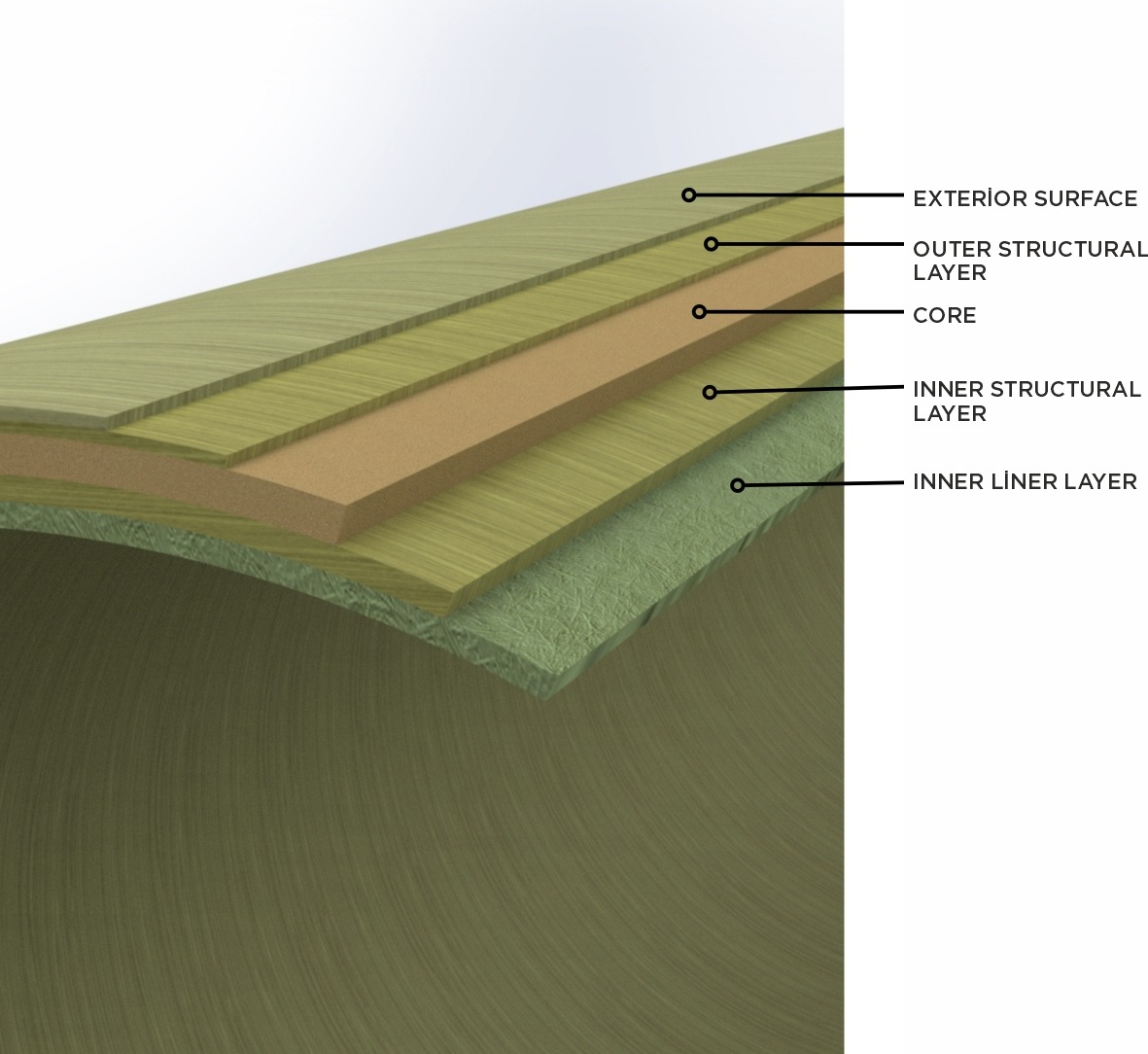

GRP pipes consist of five perfectly bonded layers, each serving different functions to ensure superior performance against internal and external conditions:

- Outer Surface Layer: Protects the pipe from external factors. Resistant to UV rays, chemicals, and mechanical impacts.

- Outer Structural Layer: Provides mechanical strength and flexibility. Prevents deformation under external loads.

- Core: Forms the main load-bearing structure. Maintains stability under high pressure and heavy loads.

- Inner Structural Layer: Ensures stability against internal pressure and other loads. Reinforces the pipe's internal structure.

- Liner Layer: Protects the inner surface of the pipe, offering chemical resistance and a smooth flow surface. This layer plays a critical role especially in transporting aggressive chemicals.

Each layer is combined through specialized engineering calculations and quality control processes, allowing our GRP pipes to function flawlessly for many years even under the most demanding conditions.

The GRP pipes produced at our Malatya factory not only offer high durability and long lifespan but also provide flexible solutions for customer needs with a wide range of diameters and lengths. The diameter range from 300 mm to 4000 mm and various length options are among the most important indicators of Kuzeyboru’s product diversity. Additionally, our pipes can be manufactured in different pressure classes to provide tailored solutions for each project.

- Wide Diameter Range: Diameter options from 300 mm up to 4000 mm make the pipes suitable for both small-scale projects and large industrial applications.

- Various Lengths: Thanks to the continuous fiber winding method, pipes of 12 meters, 15 meters, and even longer can be produced, accelerating installation processes and reducing costs in large projects.

- Different Pressure Classes: Our pipes can be produced in various pressure classes, making them suitable for water supply, wastewater systems, industrial applications, and more.

GRP (Glass Reinforced Plastic) pipes offer a wide range of diameter options suitable for different infrastructure projects. Pipe diameters are determined according to the application area and the properties of the fluid to be transported. Kuzeyboru produces GRP pipes ranging from DN300 mm to DN4000 mm. Fiberglass pipes are primarily classified based on nominal diameter (DN), pressure class (PN), and stiffness values.

Diameter selection for fiberglass reinforced pipes should be based on hydraulic calculations, flow rate, pressure requirements, and specific project needs. Larger diameter pipes are preferred in high flow-rate fluid transport systems, while smaller diameters are commonly used for drinking water and irrigation systems.

- DN300 mm - DN1000 mm: Used in drinking water, irrigation, and small-scale infrastructure projects.

- DN1100 mm - DN2000 mm: Ideal for medium-sized drinking water and sewage systems.

- DN2100 mm - DN4000 mm: Preferred for large-scale infrastructure projects, water transmission lines, and drainage systems.

This wide diameter range, supported by various pressure and stiffness classes, offers solutions suitable for every project. Additionally, custom diameters can be produced upon customer request for special projects. Kuzeyboru’s GRP pipes provide reliable solutions in infrastructure projects by ensuring optimal flow capacity alongside high durability and long service life.

Fiberglass reinforced pipes are durable and lightweight piping systems produced for various infrastructure needs. Different types such as pressure pipes, wastewater pipes, biaxial pipes, and jacking pipes serve a wide range of applications from water transmission to sewage. Their high strength and long-lasting nature provide trustworthy solutions.

Pressure GRP pipes are manufactured to withstand pressures up to 32 bar and have a broad range of applications. They are safely used in potable water transmission lines, pressurized drainage and wastewater pumping lines, irrigation systems, and various infrastructure projects. Their lightweight structure facilitates easy installation and low operating costs. Being corrosion-resistant, they offer many years of maintenance-free operation. Suitable for both underground and above-ground applications, they stand out with their durability.

Jacking pipes are specially designed for trenchless infrastructure solutions and are effectively used in micro-tunneling and pipe jacking applications. Thanks to their high axial pressure resistance, they deliver superior performance compared to traditional pipe materials. Particularly advantageous in urban infrastructure projects, they allow pipe installation without excavation in confined spaces. They can be produced with nominal stiffness up to 1,000,000 N/m² and offer special length options tailored to project requirements.

Click to view the table…

Fiberglass Reinforced Plastic (FRP/GRP) pipes offer durable solutions preferred in infrastructure projects due to their high strength, lightweight structure, and corrosion resistance. Kuzeyboru has a broad capacity producing pipes ranging from DN300 mm to DN4000 mm in diameter.

1. Wide Range of Diameters and Pressure Classes

Kuzeyboru’s fiberglass reinforced pipes (GRP) are manufactured in a wide pressure range from PN1 atm to PN40 atm. Additionally, production is available in rigidity classes SN2500, SN5000, SN10,000 as well as rigidity values up to SN1,000,000.

2. High Strength and Lightweight

GRP pipes are made from a combination of fiberglass and polyester resin. This composition maintains high strength while offering a much lighter structure compared to steel or concrete pipes. Their light weight provides significant ease during transportation and installation.

3. Manufactured According to International Standards

Kuzeyboru’s GRP pipes are produced in compliance with the following international standards:

- AWWA C 950

- ISO 23856, ISO 25780

- ASTM D 3517, ASTM D 3262 ve ASTM D 3754

These standards ensure the pipes are globally accepted in terms of quality, durability, and performance.

4. Length Options and Joining Technology

Kuzeyboru GRP pipes are manufactured in standard lengths of 3m, 6m, and 12m. However, longer lengths such as 18m or custom sizes can be produced upon customer request. For pipe joining, integrated gasketed sleeves produced using REKA type and Fiber Wrapping Technology are used.

5. Corrosion and Chemical Resistance

GRP pipes are highly resistant to corrosion and chemicals, making them safe for use in potable water, wastewater, and industrial fluid transportation systems. They require no external coating, minimizing maintenance costs.

6. High Hydraulic Performance

Thanks to their smooth inner surface, these pipes prevent sediment build-up and blockages, ensuring efficient fluid flow with low friction losses. This leads to significant energy savings. The flow coefficients used for Kuzeyboru fiberglass pipes are:

7. Earthquake Resistance and Long Service Life

Due to their elastic structure, the pipes demonstrate high resistance to ground movements and earthquake risks. Fiberglass reinforced pipes offer a long service life exceeding 50 years. The axial thermal expansion coefficient ranges between 24 – 30 × 10⁻⁶ mm/mm/°C. The Poisson’s ratio for axial environmental loading varies between 0.22 – 0.29. They are resistant to UV rays; long-term tests show only surface color changes.

8. Wear and Operating Temperature Resistance

According to the Darmstadt Test Method, Kuzeyboru GRP pipes exhibit an average abrasion loss of 0.34 mm after 100,000 cycles, indicating high abrasion resistance. Since resin properties may change above 35°C, the pressure class should be downgraded by one step when used between 35°C and 50°C. Special resins enable operation up to 100°C.

Kuzeyboru GRP pipes provide safe and efficient use in infrastructure projects with their wide diameter and pressure options, high durability, and long service life. Manufactured according to international standards, these pipes offer high hydraulic performance and low maintenance costs, making them an ideal choice for engineering solutions.

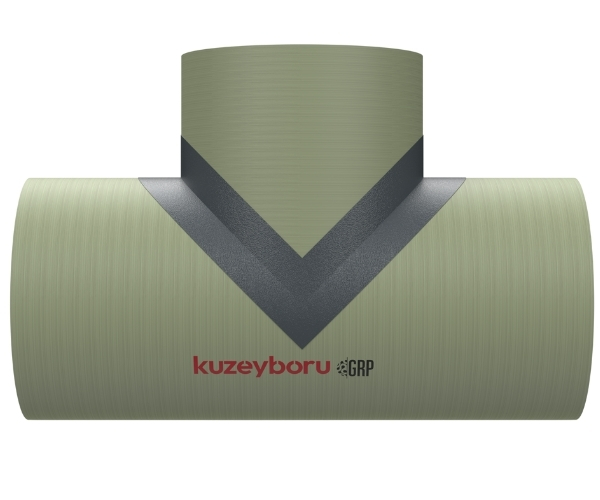

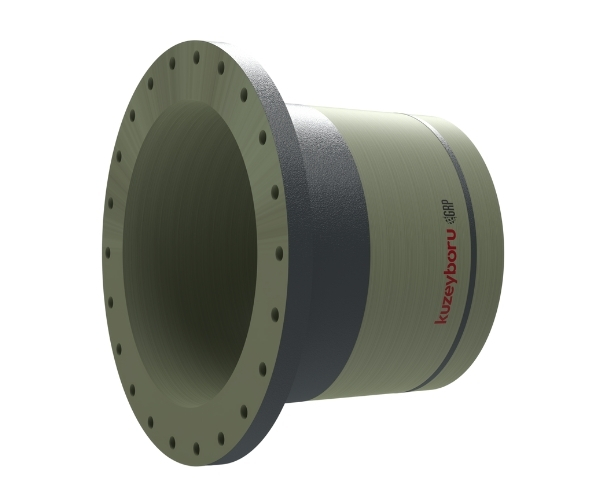

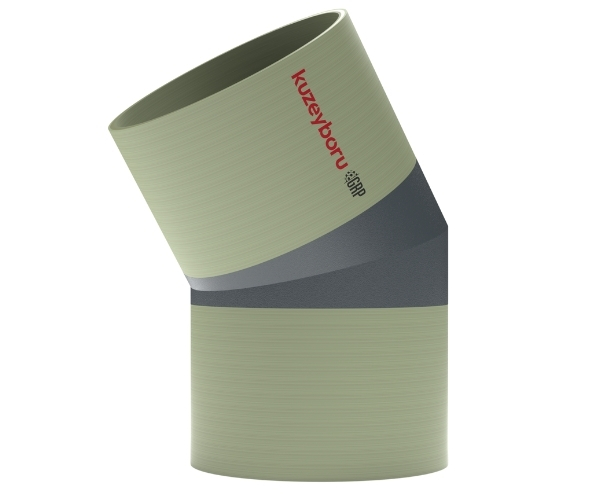

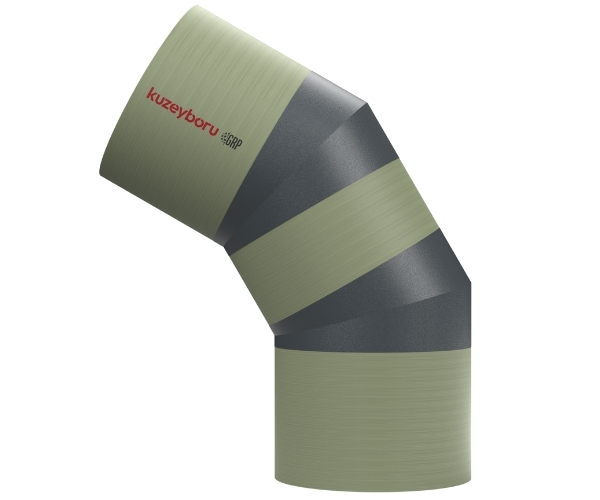

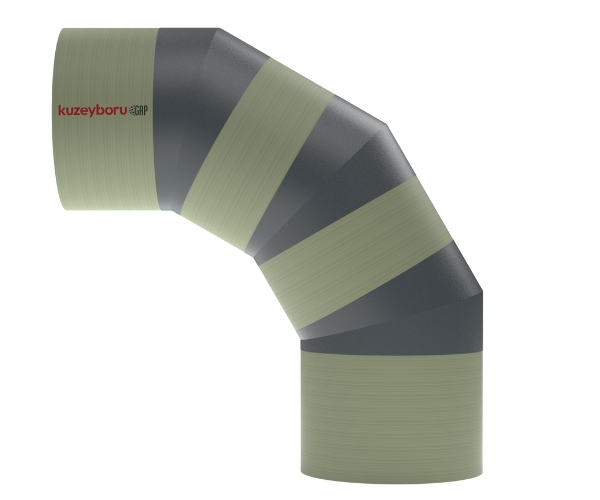

We manufacture complementary components of GRP (Glass Reinforced Polyester) pipe systems such as tees, elbows, reducers, flanges, and other special connectors at our own production facilities, adhering to high-quality standards.

Designed to meet the high durability, tightness, and long-life criteria required by GRP piping systems, these products allow easy installation in the field. They can be produced in project-specific dimensions and offer flexible solutions for different angles and diameter transitions.

You can review tables and contact our technical team for support in selecting the most suitable GRP accessories for your projects.

Kuzeyboru Standard Elbow Sizes PN6/PN10

| Number of Segments | 1 | 2 | 3 | ||||

| Elbow Angle | 11,25º | 15º | 22,5º | 30º | 45º | 60º | 90º |

| DN (mm) | L | L | L | ||||

| 300 | 350 | 350 | 400 | 400 | 500 | 550 | 750 |

| 350 | 400 | 400 | 400 | 450 | 550 | 600 | 800 |

| 400 | 450 | 450 | 450 | 450 | 600 | 650 | 900 |

| 450 | 450 | 450 | 500 | 500 | 600 | 700 | 1000 |

| 500 | 450 | 450 | 500 | 500 | 650 | 750 | 1050 |

| 600 | 400 | 400 | 450 | 450 | 600 | 700 | 1100 |

| 700 | 400 | 400 | 450 | 450 | 650 | 800 | 1200 |

| 800 | 450 | 450 | 450 | 500 | 700 | 850 | 1350 |

| 900 | 450 | 450 | 500 | 550 | 800 | 950 | 1500 |

| 1000 | 450 | 500 | 500 | 550 | 850 | 1000 | 1650 |

| 1100 | 450 | 500 | 550 | 600 | 900 | 1100 | 1800 |

| 1200 | 500 | 550 | 600 | 600 | 950 | 1200 | 1950 |

| 1300 | 500 | 600 | 650 | 700 | 1050 | 1300 | 2100 |

| 1400 | 600 | 600 | 650 | 700 | 1100 | 1350 | 2250 |

| 1500 | 600 | 650 | 700 | 750 | 1200 | 1450 | 2400 |

| 1600 | 650 | 700 | 750 | 800 | 1250 | 1550 | 2550 |

| 1700 | 650 | 700 | 800 | 800 | 1300 | 1600 | 2700 |

| 1800 | 650 | 750 | 800 | 850 | 1350 | 1700 | 2850 |

| 1900 | 700 | 750 | 800 | 850 | 1400 | 1750 | 2950 |

| 2000 | 700 | 750 | 800 | 900 | 1450 | 1800 | 3100 |

| 2100 | 700 | 750 | 800 | 900 | 1500 | 1850 | 3200 |

| 2200 | 700 | 750 | 800 | 900 | 1550 | 1950 | 3350 |

| 2300 | 700 | 750 | 800 | 950 | 1550 | 2000 | 3450 |

| 2400 | 700 | 750 | 800 | 1000 | 1550 | 2100 | 3600 |

| 2500 | 700 | 750 | 800 | 1000 | 1600 | 2200 | 3750 |

| 2600 | 700 | 800 | 900 | 1000 | 1700 | 2200 | 3800 |

| 2700 | 800 | 800 | 900 | 1000 | 1800 | 2200 | 4000 |

| 2800 | 800 | 800 | 900 | 1000 | 1800 | 2300 | 4100 |

| 2900 | 800 | 800 | 900 | 1000 | 1900 | 2400 | 4200 |

| 3000 | 800 | 800 | 900 | 1100 | 1900 | 2400 | 4300 |

| 3100 | 800 | 800 | 1000 | 1100 | 2000 | 2500 | 4500 |

| 3200 | 800 | 900 | 1000 | 1100 | 2000 | 2600 | 4600 |

| 3300 | 800 | 900 | 1000 | 1100 | 2100 | 2600 | 4700 |

| 3400 | 800 | 900 | 1000 | 1100 | 2100 | 2700 | 4900 |

| 3500 | 800 | 900 | 1000 | 1100 | 2200 | 2800 | 5000 |

| 3600 | 900 | 900 | 1000 | 1200 | 2200 | 2800 | 5100 |

| 3700 | 900 | 900 | 1100 | 1200 | 2300 | 2900 | 5200 |

| 3800 | 900 | 900 | 1100 | 1200 | 2300 | 3000 | 5400 |

| 3900 | 900 | 1000 | 1100 | 1200 | 2400 | 3000 | 5500 |

| 4000 | 900 | 1000 | 1100 | 1300 | 2400 | 3100 | 5600 |

| D1 (mm) | D2 (mm) | L (mm) | H (mm) |

| 300 | 100 | 700 | 380 |

| 150 | 800 | 400 | |

| 200 | 860 | 420 | |

| 250 | 940 | 440 | |

| 300 | 1040 | 520 | |

| 350 | 150 | 800 | 400 |

| 200 | 860 | 440 | |

| 250 | 940 | 460 | |

| 300 | 1040 | 560 | |

| 350 | 1120 | 580 | |

| 400 | 200 | 860 | 460 |

| 250 | 940 | 500 | |

| 300 | 1040 | 580 | |

| 350 | 1140 | 600 | |

| 400 | 1220 | 620 | |

| 450 | 200 | 860 | 500 |

| 300 | 1060 | 600 | |

| 350 | 1140 | 620 | |

| 400 | 1240 | 640 | |

| 450 | 1320 | 660 | |

| 500 | 200 | 860 | 520 |

| 300 | 1060 | 640 | |

| 400 | 1240 | 680 | |

| 450 | 1320 | 700 | |

| 500 | 1400 | 720 | |

| 600 | 200 | 940 | 560 |

| 300 | 1120 | 680 | |

| 400 | 1320 | 720 | |

| 450 | 1400 | 740 | |

| 600 | 1640 | 820 | |

| 700 | 200 | 940 | 620 |

| 350 | 1220 | 760 | |

| 450 | 1400 | 800 | |

| 500 | 1500 | 820 | |

| 700 | 1840 | 920 | |

| 800 | 200 | 960 | 660 |

| 350 | 1220 | 800 | |

| 450 | 1420 | 860 | |

| 600 | 1660 | 940 | |

| 800 | 2020 | 1020 | |

| 900 | 200 | 960 | 720 |

| 350 | 1240 | 860 | |

| 500 | 1500 | 920 | |

| 700 | 1860 | 1040 | |

| 900 | 2220 | 1120 | |

| 1000 | 200 | 1000 | 800 |

| 350 | 1250 | 950 | |

| 500 | 1550 | 1000 | |

| 700 | 1900 | 1100 | |

| 1000 | 2450 | 1250 | |

| 1100 | 200 | 1000 | 850 |

| 400 | 1350 | 1000 | |

| 600 | 1700 | 1100 | |

| 800 | 2100 | 1200 | |

| 1100 | 2600 | 1300 | |

| 1200 | 200 | 1000 | 900 |

| 400 | 1350 | 1050 | |

| 600 | 1700 | 1150 | |

| 900 | 2300 | 1300 | |

| 1200 | 2800 | 1400 | |

| 1300 | 200 | 1000 | 950 |

| 400 | 1350 | 1100 | |

| 700 | 1900 | 1250 | |

| 1000 | 2450 | 1400 | |

| 1300 | 3000 | 1500 | |

| 1400 | 200 | 1050 | 1000 |

| 400 | 1400 | 1150 | |

| 700 | 1950 | 1300 | |

| 1000 | 2500 | 1450 | |

| 1400 | 3200 | 1600 | |

| 1500 | 200 | 1050 | 1050 |

| 450 | 1500 | 1250 | |

| 800 | 2100 | 1400 | |

| 1100 | 2700 | 1550 | |

| 1500 | 3400 | 1700 | |

| 1600 | 200 | 1050 | 1100 |

| 450 | 1500 | 1300 | |

| 800 | 2100 | 1450 | |

| 1200 | 2900 | 1650 | |

| 1600 | 3600 | 1800 | |

| 1700 | 200 | 1100 | 1150 |

| 450 | 1500 | 1350 | |

| 900 | 2300 | 1550 |

| D1 (mm) | D2 (mm) | L (mm) | H (mm) | ||

| 1800 | 200 | 1100 | 1200 | ||

| 450 | 1500 | 1400 | |||

| 900 | 2300 | 1600 | |||

| 1300 | 3100 | 1800 | |||

| 1800 | 3950 | 2000 | |||

| 1900 | 200 | 1150 | 1250 | ||

| 500 | 1600 | 1450 | |||

| 1000 | 2500 | 1700 | |||

| 1400 | 3300 | 1900 | |||

| 1900 | 4150 | 2100 | |||

| 2000 | 200 | 1200 | 1400 | ||

| 500 | 1600 | 1500 | |||

| 1000 | 2500 | 1800 | |||

| 1500 | 3500 | 2000 | |||

| 2000 | 4400 | 2200 | |||

| 2100 | 200 | 1200 | 1400 | ||

| 500 | 1600 | 1600 | |||

| 1100 | 2700 | 1900 | |||

| 1600 | 3700 | 2100 | |||

| 2100 | 4600 | 2300 | |||

| 2200 | 200 | 1200 | 1500 | ||

| 500 | 1600 | 1600 | |||

| 1100 | 2800 | 1900 | |||

| 1600 | 3700 | 2200 | |||

| 2200 | 4800 | 2400 | |||

| 2300 | 200 | 1300 | 1500 | ||

| 600 | 1800 | 1800 | |||

| 1200 | 2900 | 2000 | |||

| 1700 | 3900 | 2300 | |||

| 2300 | 5000 | 2500 | |||

| 2400 | 200 | 1300 | 1600 | ||

| 600 | 1800 | 1800 | |||

| 1200 | 2900 | 2100 | |||

| 1800 | 4100 | 2400 | |||

| 2400 | 5100 | 2600 | |||

| 2500 | 200 | 1300 | 1600 | ||

| 600 | 1800 | 1900 | |||

| 1300 | 3100 | 2200 | |||

| 1900 | 4300 | 2500 | |||

| 2500 | 5300 | 2700 | |||

| 2600 | 200 | 1300 | 1700 | ||

| 600 | 1900 | 1900 | |||

| 1300 | 3200 | 2200 | |||

| 1900 | 4300 | 2500 | |||

| 2600 | 5600 | 2800 | |||

| 2700 | 200 | 1400 | 1700 | ||

| 700 | 2100 | 2000 | |||

| 1400 | 3400 | 2300 | |||

| 2000 | 4500 | 2600 | |||

| 2700 | 5800 | 2900 | |||

| 2800 | 200 | 1400 | 1800 | ||

| 700 | 2100 | 2100 | |||

| 1400 | 3400 | 2400 | |||

| 2100 | 4700 | 2700 | |||

| 2800 | 5900 | 3000 | |||

| 2900 | 200 | 1400 | 1800 | ||

| 700 | 2100 | 2100 | |||

| 1500 | 3600 | 2500 | |||

| 2200 | 4900 | 2800 | |||

| 2900 | 6100 | 3100 | |||

| 3000 | 200 | 1400 | 1900 | ||

| 700 | 2100 | 2200 | |||

| 1500 | 3600 | 2500 | |||

| 2200 | 4900 | 2900 | |||

| 3000 | 6300 | 3200 | |||

| 3100 | 200 | 1500 | 2000 | ||

| 800 | 2300 | 2300 | |||

| 1600 | 3800 | 2600 | |||

| 2300 | 5100 | 3000 | |||

| 3100 | 6600 | 3300 | |||

| 3200 | 200 | 1500 | 2000 | ||

| 800 | 2300 | 2300 | |||

| 1600 | 3800 | 2700 | |||

| 2400 | 5300 | 3100 | |||

| 3200 | 6800 | 3400 | |||

| 3300 | 200 | 1500 | 2100 | ||

| 800 | 2300 | 2400 | |||

| 1700 | 4000 | 2800 | |||

| 2500 | 5500 | 3200 | |||

| 3300 | 6900 | 3500 | |||

| 3400 | 200 | 1500 | 2100 | ||

| 800 | 2300 | 2400 | |||

| 1700 | 4000 | 2800 | |||

| DL (mm) | D2 (mm) | A=B (mm) | L (mm) | Toplam Boy (mm) |

| 300 | 200 | 400 | 250 | 1050 |

| 300 | 250 | 400 | 125 | 925 |

| 350 | 250 | 400 | 250 | 1050 |

| 350 | 300 | 400 | 125 | 925 |

| 400 | 300 | 400 | 250 | 1050 |

| 400 | 350 | 400 | 125 | 925 |

| 500 | 350 | 400 | 375 | 1175 |

| 500 | 400 | 400 | 250 | 1050 |

| 600 | 400 | 400 | 500 | 1300 |

| 600 | 500 | 400 | 250 | 1050 |

| 700 | 500 | 400 | 500 | 1300 |

| 700 | 600 | 400 | 250 | 1050 |

| 800 | 600 | 400 | 500 | 1300 |

| 800 | 700 | 400 | 250 | 1050 |

| 900 | 700 | 400 | 500 | 1300 |

| 900 | 800 | 400 | 250 | 1050 |

| 1000 | 800 | 400 | 500 | 1300 |

| 1000 | 900 | 400 | 250 | 1050 |

| 1200 | 900 | 500 | 750 | 1750 |

| 1200 | 1000 | 500 | 500 | 1500 |

| 1400 | 1000 | 500 | 1000 | 2000 |

| 1400 | 1200 | 500 | 500 | 1500 |

| 1600 | 1200 | 600 | 1000 | 2200 |

| 1600 | 1400 | 600 | 500 | 1700 |

| 1800 | 1400 | 600 | 1000 | 2200 |

| 1800 | 1600 | 600 | 500 | 1700 |

| 2000 | 1600 | 600 | 1000 | 2200 |

| 2000 | 1800 | 600 | 500 | 1700 |

| 2200 | 2000 | 600 | 500 | 1700 |

| 2200 | 2100 | 600 | 250 | 1450 |

| 2400 | 2200 | 600 | 500 | 1700 |

| 2400 | 2300 | 600 | 250 | 1450 |

| 2600 | 2400 | 750 | 500 | 2000 |

| 2600 | 2500 | 750 | 250 | 1750 |

| 2800 | 2600 | 750 | 500 | 2000 |

| 2800 | 2700 | 750 | 250 | 1750 |

| 3000 | 2800 | 750 | 500 | 2000 |

| 3000 | 2900 | 750 | 250 | 1750 |

| 3200 | 3000 | 900 | 500 | 2300 |

| 3200 | 3100 | 900 | 250 | 2050 |

| 3400 | 3200 | 900 | 500 | 2300 |

| 3400 | 3300 | 900 | 250 | 2050 |

| 3600 | 3400 | 1050 | 500 | 2600 |

| 3600 | 3500 | 1050 | 250 | 2350 |

| 3800 | 3600 | 1050 | 500 | 2600 |

| 3800 | 3700 | 1050 | 250 | 2350 |

| 4000 | 3800 | 1100 | 500 | 2700 |

| 4000 | 3900 | 1100 | 250 | 2450 |

| DN (mm) | H (mm) | DN (mm) | H (mm) |

| 300 | 700 | 2100 | 1100 |

| 350 | 700 | 2200 | 1100 |

| 400 | 700 | 2300 | 1200 |

| 450 | 700 | 2400 | 1200 |

| 500 | 700 | 2500 | 1300 |

| 600 | 800 | 2600 | 1300 |

| 700 | 800 | 2700 | 1400 |

| 800 | 800 | 2800 | 1400 |

| 900 | 800 | 2900 | 1500 |

| 1000 | 800 | 3000 | 1500 |

| 1100 | 900 | 3100 | 1600 |

| 1200 | 900 | 3200 | 1600 |

| 1300 | 900 | 3300 | 1800 |

| 1400 | 900 | 3400 | 1800 |

| 1500 | 900 | 3500 | 2000 |

| 1600 | 1000 | 3600 | 2000 |

| 1700 | 1000 | 3700 | 2200 |

| 1800 | 1000 | 3800 | 2200 |

| 1900 | 1000 | 3900 | 2400 |

| 2000 | 1000 | 4000 | 2400 |

GRP Coupling and Manholes: High Performance and Tightness with Kuzeyboru

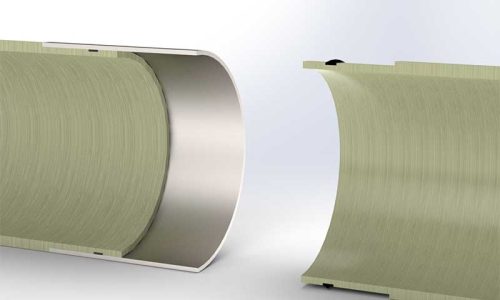

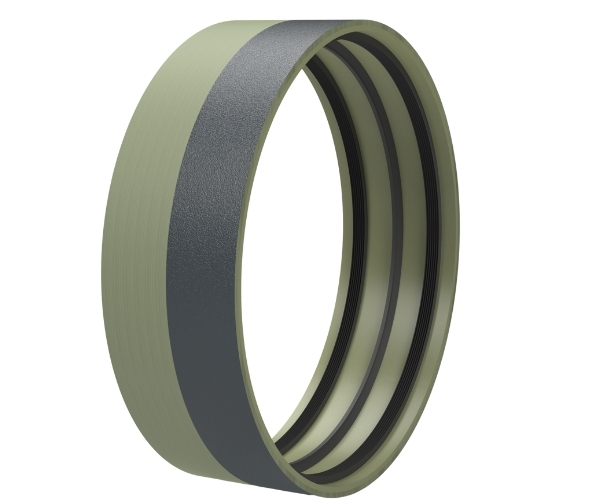

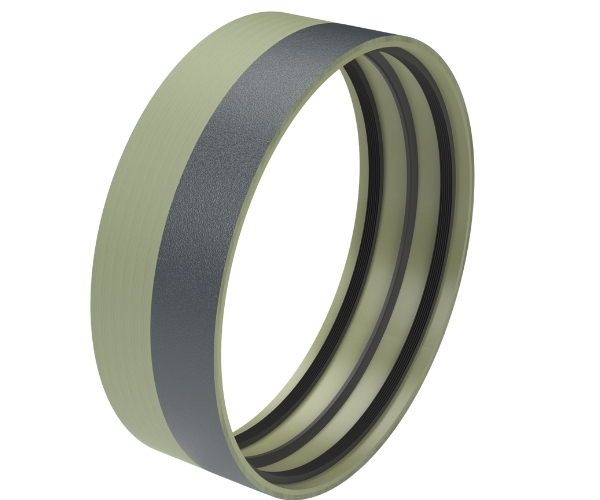

Kuzeyboru is a leading company offering GRP coupling solutions that provide excellent sealing in GRP pipe joints. With two different sleeve options REKA Type and Integrated Gasket Type Kuzeyboru offers flexibility to its customers. These coupling provide high performance and reliability in joining GRP pipes and fittings. Kuzeyboru ships GRP pipe systems together with integrated gasket or REKA type sleeves, facilitating easier assembly and ensuring leak-tightness..

Applications of GRP Manholes

- Water and Wastewater Infrastructure Projects: Ideal solutions for municipal water and sewage systems.

- Industrial Facilities: Suitable for piping systems in chemical production plants.

- Power Plants: Preferred for circulation lines and transmission lines in hydroelectric plants.

- Stormwater and Drainage Systems: Suitable for sewer and drainage networks.

- Subsea Pipe Applications: Used in underwater projects with their robust structure.

Advantages of GRP Manholes

- Long Service Life: Offers an economical solution with a minimum service life of 50 years.

- Corrosion Resistance: Exhibits superior resistance to corrosion across a wide pH range.

- Lightweight: Much lighter than steel, cast iron, or concrete manholes, facilitating transport and installation.

- Smooth Inner Surface: Provides efficient water and wastewater flow with low hydraulic losses and minimal friction.

- Integrated Gasket Connection: Offers leak-proof and reliable connections with a full-face elastomeric gasket system.

- Fast Installation: Can be easily installed without special equipment, saving time and cost.

Why Choose Kuzeyboru GRP Couplings and Manholes?

Kuzeyboru has proven its reliability in the sector with its GRP Couplings and manholes. The products are manufactured according to high-quality standards and offer a guarantee of long-lasting performance. GRP sleeves ensure leak-proof pipe joints, while GRP manholes stand out for their resistance to harsh industrial conditions. Kuzeyboru provides a wide product range and technical support, accompanying you at every stage of your projects.

Contact us now for more information about GRP couplings and manholes and discover the solutions Kuzeyboru offers!

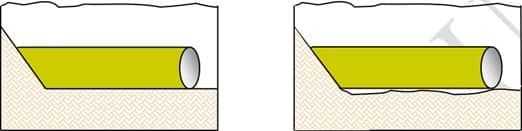

Kuzeyboru stands out in the sector with its advanced technology and quality-focused approach in manufacturing GRP (Glass Reinforced Polyester) pipes. The laying methods of GRP pipes vary depending on pipe rigidity, soil cover depth, soil properties, and the backfill materials used. Kuzeyboru maintains superior quality standards in these processes, offering long-lasting and reliable solutions to its customers.

The installation of GRP pipes varies according to the pipe’s technical specifications, soil cover depth, soil structure, and the backfill materials used. The trench width should be planned to ensure proper placement of fittings and effective compaction of the backfill material. Especially in low-quality soil conditions, trench width can be increased to ensure pipe stability.

Compaction of Backfill Over Pipe and Deflection Control

Kuzeyboru GRP Coupling Installation

Kuzeyboru also offers superior quality and ease of use in GRP coupling installation. REKA Type and Integrated Gasket Type coupling, combined with Kuzeyboru’s production technology, accelerate installation and ensure a reliable joint.

REKA Type GRP Couplings

- Gasket grooves and rubber gaskets are cleaned from dirt and oil.

- EPDM gaskets are properly seated in the sleeve groove and pressed evenly.

- A rubber mallet is used to ensure the gasket protrudes evenly from the groove.

Integrated Gasket Type GRP Couplings

These couplings are produced with Kuzeyboru’s special manufacturing technology and do not require a gasket installation process.

Manufactured by wetting the fiber with resin and winding, these couplings simplify the installation process.

Kuzeyboru delivers GRP pipes and fittings to the site with REKA or Integrated Gasket Type couplings unless otherwise specified. Before installation, the pipe ends are cleaned and checked for delamination. During pipe laying, a trench is dug where the coupling will be seated, designed to facilitate the joining process. After installation, these trenches are filled with bedding material and compacted.

With its production technology and quality diversity, Kuzeyboru continues to be a pioneer in GRP pipe applications. Its product range offers solutions suitable for various project needs. Kuzeyboru GRP pipes will be a reliable part of your projects when installed and laid correctly. For more information, you can refer to our GRP installation catalog.

Frequently Asked Questions about GRP Pipes

A GRP pipe is a lightweight, durable pipe made from glass reinforced plastic. Due to its corrosion resistance, it is widely used in potable water, wastewater, irrigation, and industrial facilities.

GRP pipe is a type of composite pipe produced using glass fiber and polyester resin. Due to its high strength, long service life, and low maintenance costs, it is a preferred solution in infrastructure projects.

GRP stands for "Glass Reinforced Plastic." This material is produced by combining glass fiber, polyester resin, and various additives, providing high durability and lightness.

Glass fiber pipes have a lifespan of over 50 years depending on usage conditions. Thanks to their corrosion-resistant structure, maintenance requirements are minimal, and they can be used safely for many years.

Glass fiber reinforced pipes are widely used in potable water lines, wastewater and sewerage systems, agricultural irrigation, power plants, sea water discharge lines, and industrial facilities. With their lightweight and durable structure, they offer an ideal solution in many sectors.